Industry 4.0, the fourth industrial revolution, involves a combination of traditional manufacturing and industrial platforms and practices with the latest smart technology. It primarily focuses on the use of computers for machine communication and the implementation of the Internet of Things (IoT) to provide increased automation, improved communication and self-control, as well as smart computers that can analyze and diagnose problems without the need for human intervention.

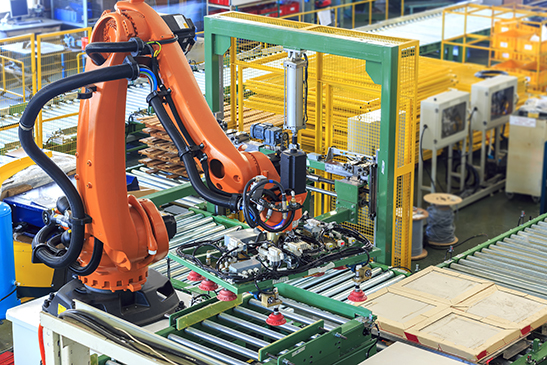

Accordant with the entire technological revolution, the logical sequence is the development of robots both in industry and in services, households, etc. When we think globally, robots are used in almost all industries today, but some rely on robots more than others. The increased demand for robotically controlled warehouses is driven by the need for improved quality and reliability and the growing e-commerce industry. Croatia is still in its infancy in this area, but slowly croatian companies (as well as the regional ones) are moving towards technological innovation and thus robotics.

Accordant with the entire technological revolution, the logical sequence is the development of robots both in industry and in services, households, etc. When we think globally, robots are used in almost all industries today, but some rely on robots more than others. The increased demand for robotically controlled warehouses is driven by the need for improved quality and reliability and the growing e-commerce industry. Croatia is still in its infancy in this area, but slowly croatian companies (as well as the regional ones) are moving towards technological innovation and thus robotics.

Computer intelligence is expanding and enables the connection of more devices and mutual communication, which means larger amounts of big data. When we put it all in the context of a warehouse, it fits the needs of the warehouse perfectly. In the warehouse, SKUs (inventory storage units) communicate with the machines, the machines connect and communicate with other machines, and then they connect and communicate with the WMS.

This mini ecosystem in itself drives distribution operations for your warehouse. It can respond to any updates in the to-do list, and the included robotics can be reconfigured to respond in real time without involving human “colleagues”. These technologies are not only more reliable and cost-effective than ever before, but are also more widely available for a range of applications. Warehouse automation reduces the logistics industry’s dependence on manpower, and Industry 4.0 provides a much-needed solution to disrupt this productivity through an integrated system and intelligent, collaborative robots that can work together with people in the warehouse.

At the beginning of June 2020, the first pallet commissioning robot in Croatia was put into production. Primat informatika performed the software part of the work as part of its PrimatWMS solution. This is a project we are extremely proud of for a number of reasons. On the one hand, due to the technology on which it is based, we are also pleased with the fact that we are pioneers among WMS manufacturers that we can perform such a complex project, but we are most proud of our customers who have recognized us as an ally and a partner that they can rely on and count on us when more is expected in the area of knowledge and technological innovation. The project was done in cooperation with the company Demateh and the installation of the robot is located in the logistics and distribution center Jamnica in Jastrebarsko. We have been cooperating with Jamnica for many years to our mutual satisfaction, all warehouses are covered by our PrimatWMS system and they are first on our list in terms of the size of transactions and the amount of data that passes through WMS.

At the beginning of June 2020, the first pallet commissioning robot in Croatia was put into production. Primat informatika performed the software part of the work as part of its PrimatWMS solution. This is a project we are extremely proud of for a number of reasons. On the one hand, due to the technology on which it is based, we are also pleased with the fact that we are pioneers among WMS manufacturers that we can perform such a complex project, but we are most proud of our customers who have recognized us as an ally and a partner that they can rely on and count on us when more is expected in the area of knowledge and technological innovation. The project was done in cooperation with the company Demateh and the installation of the robot is located in the logistics and distribution center Jamnica in Jastrebarsko. We have been cooperating with Jamnica for many years to our mutual satisfaction, all warehouses are covered by our PrimatWMS system and they are first on our list in terms of the size of transactions and the amount of data that passes through WMS.

Given the trends in industry and logistics, we believe that this is only the first in a series of projects with robots, and which of our users (or someone new) will move in the direction of modernization, time will tell. In order for companies to take the lead in the market, they need to embrace change and new technologies and direct resources to technological advances that ultimately lead to more efficient and profitable operations.

For more information about automated warehouses and robots within the warehouse, contact us at [email protected]